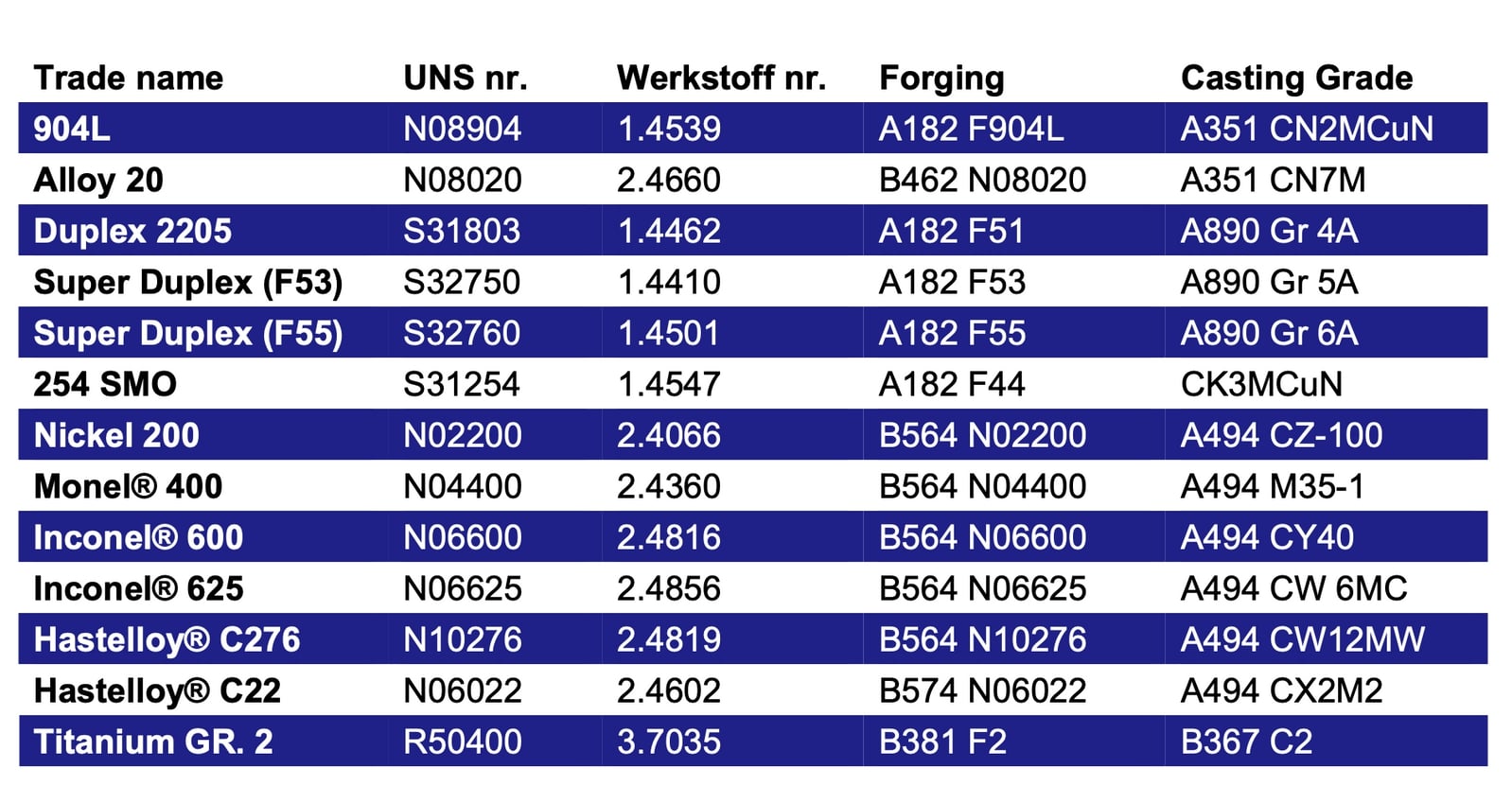

Anson Flow provides standard material such as CF8M, WCB, CF8 & CF3M in ASME standard or 1.4408, 1.4308, 1.0619 in EN standard or SCS14, SCS13, SCS16 in JIS standard. For special alloy, we offer both in valve field and other investment casting parts according to your drawings & requirements.

Material often stocked in 2-pc Flanged RF & High Performance 3-pc Firesafe Ball Valves.

Each shipment of Anson Flow’s valves and casting parts includes EN10204 3.1 material certification, demonstrating our unwavering commitment to delivering products of the highest quality and strict adherence to industry standards.

Features high corrosion resistance and strength, ideal for chemical processing, oil and gas exploration, and marine environments.

Exhibits exceptional corrosion resistance, perfect for heat exchangers, pipes in gas and oil processing, and cargo tanks in chemical tankers.

Well-suited for corrosive environments, widely used in pulp bleaching plants, gas cleaning systems, and seawater-handling equipment.

Utilized in severely corrosive media with high chloride and temperature applications, including buffer solutions and fabric softeners.

Nickel-molybdenum-chromium superalloy with excellent corrosion resistance, widely used in chemical processing, pollution control, and pulp production.

Designed for sulphuric acid applications,offers corrosion resistance in chemical, food, pharmaceutical, and plastics industries.

Commercially pure nickel with high corrosion resistance, suitable for plant processes exposed to caustic soda and anhydrous hydrofluoric acid.

Excels in corrosion resistance in reducing environments, suitable for chemical processes dealing with alkali chlorides and oil refining.

Offers strength and toughness across temperatures, used in process heaters and high purity water systems in nuclear reactors.

Known for exceptional corrosion resistance, fatigue strength, and high-temperature strength, widely used in chemical and food processing.